With the increasing accuracy and precision of microelectronic semiconductor filtration, perfluorinated filtration, highly corrosive chemicals and gas filtration environments, the need for high temperature, corrosion-resistant, high strength, lightweight and high density filtration membranes and new materials for filtration media become more relevant when developing technologies. PALL, and Parker Hannifin, domestic and well-known filter manufacturers, have used this kind of precision extension technology to manufacture different materials as filter membranes and filter membrane support materials;

according to different materials, the extended polymer film PolyGrid® can be used as different filter membranes and filters. Media such as: filter support mesh, industrial separation and purification, primary purification, fuel cell separators, etc. Dexmet custom manufactures PolyGrid® high performance materials from fluoropolymers and thermoplastics with controlled pore sizes to provide proper particle removal with more consistent flow rates and pressure drops for your filter application.

· Advantage:

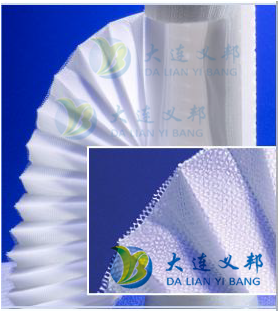

· Assured Media Integrity & Pleat Clearance Even Under Dynamic Flow

· Increased Filter Surface Area for Pleated Designs (Capability to Expand Thinner Materials to Achieve a Reduced Overall Thickness)

· Materials Laminate for Contraction, Co-Expansion, and Flex with Filter Membranes (Material Compatibility with Membranes)

· PolyGrid® Common Polymers

PTFE、PEEK、PP、 PE、 PFEP、 PCTFE、PVF、PVDF、 PFA 、ECTFE

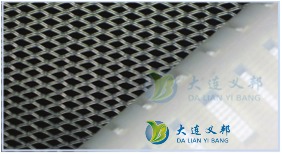

· MicroGrid® Common Metal materials:

Stainless steel、Aluminium、 Nickel alloy、Steel、Copper, DEXMET has the ability to extend all ductile metal.

Weixin