Microelectronic filtration

Release date:2018-09-12 Author:DLYB Viewing count:6509

With the increasing accuracy and precision of microelectronic semiconductor filtration, perfluorinated filtration, highly corrosive chemicals and gas filtration environments, the need for high temperature, corrosion-resistant, high strength, lightweight and high density filtration membranes and new materials for filtration media become more relevant when developing technologies. PALL, and Parker Hannifin, domestic and well-known filter manufacturers, have used this kind of precision extension technology to manufacture different materials as filter membranes and filter membrane support materials;

According to different materials, the extended polymer film PolyGrid® can be used as different filter membranes and filters. Media such as: filter support mesh, industrial separation and purification, primary purification, fuel cell separators, etc. Dexmet custom manufactures PolyGrid® high performance materials from fluoropolymers and thermoplastics with controlled pore sizes to provide proper particle removal with more consistent flow rates and pressure drops for your filter application.

· Design Considerations

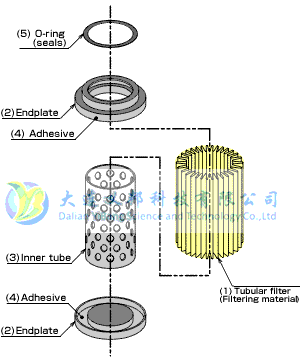

Filtration Rating: Particulate passage is controlled by the opening size or “pore” diameter of the media and is designated by a Micron rating. The opening configuration (pore) might be diamond-shaped (expanded), square (woven wire), or round (perforated). The opening specification is in accordance to the particle size required to be separated out of the flow path.

Back pressure: Flow back pressure results from the “percent open area” and the degree of particulate build-up on the media surface. The material selected can withstand the full pressure drop across a blocked surface area.

Filter Strength: Ultimate strength is controlled by material selection, thickness, percent open area and pore geometry. Multiple layers of filter material with various openings can improve flow, purification, and withstand higher back pressure.

· Advantage:

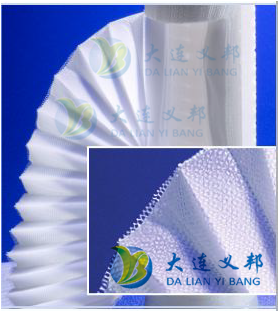

· Assured Media Integrity & Pleat Clearance Even Under Dynamic Flow

· Increased Filter Surface Area for Pleated Designs (Capability to Expand Thinner Materials to Achieve a Reduced Overall Thickness)

· Materials Laminate for Contraction, Co-Expansion, and Flex with Filter Membranes (Material Compatibility with Membranes)

· PolyGrid® Common Polymers

PTFE、PEEK、PP、 PE、 PFEP、 PCTFE、PVF、PVDF、 PFA 、ECTFE

· MicroGrid® Common Metal materials:

Stainless steel、Aluminium、 Nickel alloy、Steel、Copper,

DEXMET has the ability to extend all ductile metal.

Weixin