New energy technology for battery

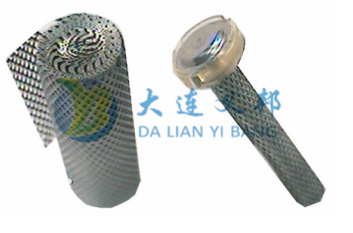

Release date:2018-09-12 Author:DLYB Viewing count:6458The electrically active material used in the electrodes of most modern battery designs are powders and require a mechanical support structure to hold them in place during the manufacturing process. This support structure also functions as a current collector and provides the electrical connection point for the external circuit.

Dexmet expanded metal foils are also used in fuel cell and electrolyzer industries where it is required that electrodes allow the flow of fluids. The unique open-area geometry of our proprietary expansion process makes our materials well-suited to be used as the catalyst substrate or gas diffusion layer for these applications.

Application in Power technology for Dexmet expanded metal foils :

Application for Advanced battery technology (non-rechargeable battery)

The optimum structure of active materials is grid geometry. DEXMET's special extended process geometry is the best choice for this application.

Application advantages of expanded metal mesh in Battery:

Extensive range of materials——Dexmet Corporation can expand any ductile metal. Our engineers can assist you in selecting the most appropriate metal to meet conductivity requirements for your battery.

Specific Conductivity——Each material contains numerous specifications that allow for specific resistivity requirements. Our sales and engineering staff can help tailor these parameters to meet the requirements set forth in your specific battery.

Increased Surface Area——The unique 3D geometry of expanded mesh provides surface area when seeking optimal adhesion and active material packing.

Application for Typical Battery:

SO2

Li-SOCl2

MnO2

Zn Air

Application of secondary rechargeable battery:

Using an expanded metal mesh in place of solid foils provides greater surface area per unit weight of metal in the battery. This results in better adhesion of the electrode layers and higher ion transport rate, thus greater energy density capabilities.

Application advantages of expanded metal mesh in second battery:

Increase cycle life

Decrease internal resistance associated with cycling and age

Improve battery capacity

Application for Typical Battery :

Ni-MH

PLI

Li-ION

Zn Air

other

Application of fuel cells:

Fuel Cell stacks are made up of several layers of material. The versatility of MicroGrid and PolyGrid expanded materials can be utilized in many of these layers to increase performance and reduce cost

Application advantages of expanded metal mesh in Fuel cells:

Excellent as a Catalyst Substrate——The open area design allows for more surface area to deposit the catalyst. The open area design allows for better flow through the catalyst improving ion separation.

Gas Diffusion Electrodes, Flow Field Structures and Current Collector Screens——The 3D geometry allows for more consistent diffusion over the catalyst, therefore increasing efficiency

Membrane Support Grids——As stack pressures increase the need for membrane support materials becomes essential to reduce the amount of flex the membrane is subjected to during operation. MicroGrid® and PolyGrid® materials are perfect support materials for reducing the amount of flex without affecting flow through the system.

Application For Typical Fuel cells :

PEM

DMFC

SOFC

AFC

MCFC

PAFC

Weixin