Communication sensors

Release date:2018-09-12 Author:DLYB Viewing count:6686Wearable flexible fabric antennas can be generally divided into two categories. One type is based on the textile or embroidery process, the conductive fibers are stitched onto the fabric matrix according to the structure of the antenna; the other is based on the inkjet printing/coating process, and the flexible wearable fabric antenna is produced by printing nano-conductive particles or coating conductive polymer according to the antenna structure. The flexible antenna is a new concept antenna, which utilizes flexible materials to make the whole antenna soft and pliable. SYSCOM is the world's leader in design and production of ultra-lightweight for military, aerospace and other critical applications, and its proprietary process independently coats each filament to maintain the textile nature and characteristics of underlying polymer yarn.

Created from an Air Force research lab,

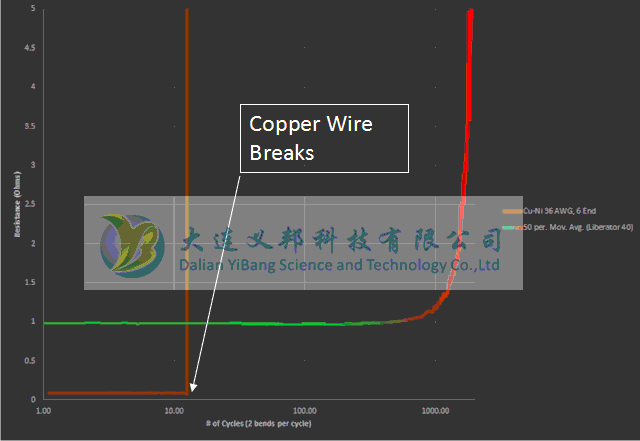

SYSCOM developed three super light metallized fibers: Lyofil 、Liberator and X-STEEL.By the perfect combination of non-metallic base material flexibility and metal coating conductive,we offers a variety of solutions for the new type of flexible antenna.

Ultra-light-plated metal wire Lyofil®, Libator®, and X-STEEL® offers non-metallic substrate flexibility and metal coating conductivity, providing a variety of solutions for new flexible antennas.

Weixin